White Paper: Live Rosin Process Management: Strain Selection, Ice Water Hash, and Finished SKUs

Abstract

Live rosin, which is made from fresh frozen cannabis that is washed into ice water hash and then pressed into a variety of premium SKUs, is rapidly becoming a key high-end product that connoisseurs seek at dispensaries. Many extractors are unaware of the true versatility that live rosin offers, as it can also be processed into 100% solventless rosin vaporizer cartridges, diamonds and sauce, edibles, and many more products that consumers seek. Solventless-based SKUs offer a unique opportunity for cannabis brands to differentiate their manufactured or concentrated products that solvent-based extraction methods such as hydrocarbon, distillate, CO2, and ethanol do not provide due to their ubiquitous use. Achieving predictable outputs and consistency when making live rosin solventless SKUs is relatively simple with the right planning, strain selection, equipment, and SOPs. This white paper outlines exactly how new and existing processing laboratories can begin making live rosin SKUs successfully and will focus on how fresh frozen, THC dominant material can be best used for this purpose. While CBD applications are not closely considered, it is worth noting that CBD dominant strains are in the process of being bred to yield more profitably for live rosin processing.

Overview

Live rosin and solventless SKUs have risen to prominence in the cannabis concentrate landscape relatively quickly, posting startling growth in certain maturing markets. While data is not complete across different states where cannabis is legal either medicinally or recreationally (or Canada, for that matter), some signs point to mind boggling growth potential. For example, between May 2019 to May 2020, Oregon saw 390% sales growth in the rosin category according to BDSA’s state sales report (BDS Analytics, 2020). While live rosin is a staple product that dispensaries sell en masse to consumers in Colorado and California, as more states market’s mature, top shelf solventless SKUs are now a necessary processing endeavor that extraction operations are undertaking to stay competitive.

While there are many aspects to successfully adding a solventless processing division to an existing laboratory, or to start a net new processing business that focuses on or includes live rosins as a key go to market product, there are a few elements that deserve the most attention. Primarily, these operations need to center their efforts on the following:

- Setting clear processing output goals based on desired SKUs, operating space, and business objectives.

- Cultivating or purchasing the right kinds of fresh frozen cannabis that will yield profitably when washed into ice water hash.

- Streamlining and dialing in the finer points of ice water hash production to maximize yield and product quality potential.

- Processing the finished ice water hash, using a rosin press, based on grading the quality and size of the trichomes produced into the solventless SKUs best suited for their market and brand goals.

Processing operations that are new to solventless often discover barriers on the first or second item described previously: they aren’t sure which solventless SKUs they should produce, or they do not have the right parameters to source the kinds of material that will be profitable for their business. As a reader if you feel that you do not have a strong grasp of the different solventless SKUs that are available or which ones your business may want to pursue, it is worth your time to go read the first white paper in our series afterwards to better understand your options. The first item on the previous list is discussed in copious detail so that readers can better align their business objectives with the task at hand, which is absolutely crucial to success.

Live rosin is called as such because the starting cannabis flowers used in the ice water hash washing process are stripped of their fan leaves and then frozen in bags, which is known as “live” in industry nomenclature. From an operator’s perspective, skipping the space intensive, lengthy drying and curing process virtually always makes financial sense as well when making a solventless concentrate. The terms “live rosin” and “hash rosin” are used almost interchangeably in the industry because so much of the ice water hash produced is made with fresh frozen cannabis. The same goes for “bubble hash” and “ice water hash” as these terms both refer to the same product. For our purposes, we will primarily use the term “ice water hash” to be specific. The corollary most are familiar with is live resin, in which the starting material takes the same path on its way to being extracted using hydrocarbons. Ice water hash can be made with either live or dried and cured cannabis, but consumer preferences seem to strongly lean towards the taste and aroma profile that live rosins offer. Old World-style hashish is making a comeback however, being made with “live” based ice water hash as well, in the form of hand pressed hash and full spectrum ice water hash sold as-is, mainly as a bowl topper.

Live rosin SKUs in budder, batter, or jam-type consistencies have so far been the key staples of most solventless processing operations. Given how popular solventless vape cartridges are becoming however, the convenience of enjoying a 100% solventless rosin vape anywhere is unrivaled. Making these solventless designer vape cartridges is now one of the top objectives most solventless extraction divisions are striving for to attract those kinds of customers with high disposable incomes and discerning tastes. In less mature markets or markets where less of those consumers exist, largely due to the vacuum of education that is now being filled concerning the differences surrounding solventless products, hash rosin-infused pre-rolls, edibles, and other products are very compelling to newer cannabis purchasers.

Strain Selection

The topic of selecting the “correct” strains to wash in the ice water hash process is one that most new processors typically know is critically important, long before they do their first wash. The reason being that in solventless extraction, many strains under-perform and do not hit target yields that are required in order to be successful, due to a myriad of factors. Truly, only the very best material should be considered for the ice water hash washing process and when done properly, the rewards are ample.

The first important part of selecting strains that will be profitable when made into live rosin or standalone ice water hash SKUs is to understand how to think about yields so that your business can extrapolate small test washes to larger batches. Since fresh frozen cannabis buds are typically what are being washed into ice water hash, they retain a large percentage of moisture that is dried out of shelf-ready flower. In a standard pound of fresh frozen cannabis buds, the ratio of water to plant material is typically between 75%-80% water to 25%-20% cannabis. So, yields when washing from fresh frozen into ice water hash are expressed in single digit percentage points, such as:

- A low yield is around 1-2%. When multiplied by 4.5x, that means if your strain can only yield 2% for example, that actually means you are receiving a 9% dried hash yield.

- An average yield is around 3%. By the same math, that means that you are getting a 13.5% yield to dry hash. This is usually the amount most businesses need to hit to break even on any particular batch.

- Great yields are anywhere from 4-6%, with some of the very best strains yielding 7% or more. If your strains yield 5%, that means a 22.5% return from fresh frozen cannabis to a dried ice water hash.

To complete the picture, high quality ice water hash will then yield anywhere from 60%-90% into a final live rosin product. So, if you have a terrific strain that yielded 5% in your ice water hash washing process, and that yielded 80% into live rosin, your final yield from fresh frozen, wet cannabis to finished live rosin is 18%.

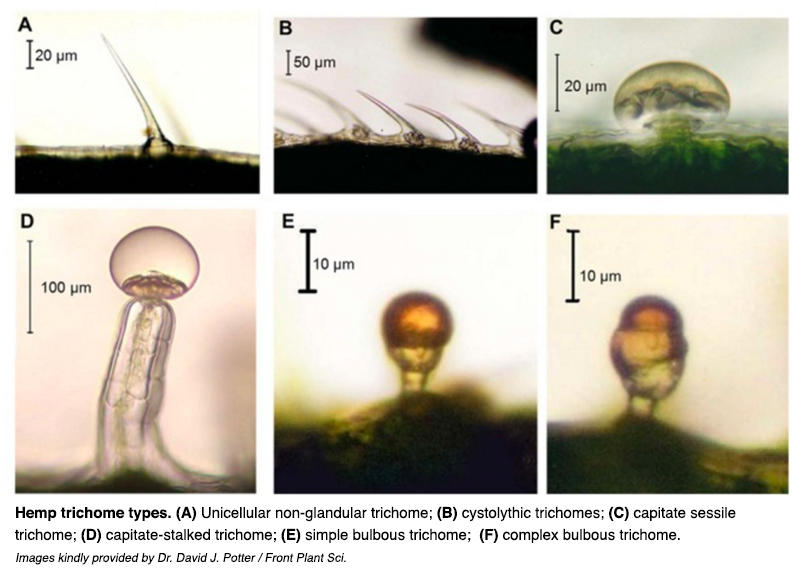

While there are many strains to look for, the best analogy is very resinous strains that are often hybrids and indicas tend to wash the best because there is more “juice to squeeze”, as it were. You want to identify strains that are highly resinous and produce large, glandular trichome heads. In the image below, “D” represents the ideal trichome type because the trichome heads are most easily capturable and detachable. The perfect trichome for solventless processing has a large glandular head, a thin neck, and a medium length stalk. The standard micron filter range is between 25μm and 160μm to capture these types of trichomes. That means that images A, C, E, and F are unlikely to be captured well since they are so small. In image B, you see a cystolythic trichome which is spine-like and is also rather difficult to capture. Many hemp strains tend to produce trichomes on the very small end of the spectrum, hence why so much energy and attention is being put into cultivating CBD strains that produce the right types of trichomes to be captured in the wash process.

(Porter, 2017)

It is highly advisable to seek strains that are known to be prolific washers, whether you are vertically integrated and cultivating your own material or are purchasing third party. While this seems obvious, having this objective in mind when curating material should be the focus. The growing staff on your team should be knowledgeable on this topic, and if they aren’t, push them to start researching it themselves to improve their acumen on cultivating solventless-friendly material. It is also especially important when or if you are purchasing material to ask the grower if they have particular strains that they know yield well in solventless. This material specialty is becoming much more common and high-quality strains that yield well in the ice water hash wash process are now more easily found as more breeders create strains specifically for the purpose.

While phenotype hunting is still crucial, and a given clone of any of the following strains may not be a high yielder necessarily, the following list is a great place to get started when seeking strains that wash well:

- Chem Dawg, Chem Strains

- Gorilla Glue, Glue Strains

- Cookies & Cake Crosses

- The White, White Crosses

- Gelato, Sherbert Crosses

- Cookies & Cream Strains

- GMO (Garlic Cookies) (Chem Cookies). GMO Crosses

- MAC (Miracle Alien Cookies), MAC Crosses

- Papaya Strains

- Tropicana Cookies

- Sour Kosher, Many Sour Strains

- Pie Strains

- Sugar Coat

Lastly, we would encourage anyone who is responsible for material cultivation or procurement to become a student of the ice water hash washing community by following top hash makers where they showcase their work best; on Instagram. While they will not share their cuts and clones, they will share which strains are helping make their top hashes and live rosins so that your business can more closely follow ever changing consumer taste trends in solventless.

Ice Water Hash

Ice water hash is the go-to starting material for live rosin for most solventless processors because it is currently the most commercially viable way to scale the capture and isolation of trichomes in a solventless manner. While many processors are also creating and capturing incredible dry sift, this process still is lacking scalable means of doing so as of this writing. That will certainly change in the coming years. Because the goal of ice water hash is to detach and capture cannabis trichomes intact, as opposed to dissolving them in the way solvent-based processes do, it gives the processor many more options for finished SKUs than flower rosin can typically offer. Flower rosin certainly has a place in the market, however.

When setting out to make ice water hash, there are certain variables that professional hash makers cite time and time again as the top variables to control for. Those include the cleanliness of your laboratory environment, using RO (reverse osmosis) water and RO ice in the wash process, utilizing a cold environment if at all possible (washing in a warm room is never advised), and leveraging freeze dryers to dry your hash as opposed to air drying to mitigate mold and microbial growth as well as to speed up the drying process. All of these in turn are not difficult to achieve but do require proper planning and protocols to ensure consistency in the wash process to produce more repeatable results.

On the right we have an example of Do-Si-Dos ice water hash from Kush Masters, out of Boulder, Colorado. This macro image shows up close a pile of detached trichome heads that have been separated and dried. Ice water hash is created by filling a vessel with fresh frozen cannabis, ice, and water. This cold temperature environment induces brittleness in the trichomes, which are then detached from the cannabis buds by agitation. This is typically performed by hand washing to ensure the best results, but automated solutions are quickly coming to the fore to scale the process at commercial facilities.

The batch is then drained or pumped and then filtered through a series of different sized mesh aperture filter bags to capture the different sized trichome heads and stalks, which come in a variety of different sizes. The most common sizes that the very best trichomes are found are between 73μm and 120μm, however some hash makers are starting to discover premium trichomes from certain strains above 120μm as well.

Once the wet slurry of trichomes has been graded in the filter bags, it is gently scooped onto parchment-lined freeze dryer trays. Many processors will either collect and combine multiple microns together into a “full spectrum” mix, which is common for live rosin products, or will keep their different trichome types separate to differentiate quality types (think “top shelf” versus “mid shelf” and similar grading systems that are ubiquitous in dispensaries). The entire wash process typically takes anywhere from 1 to 1.5 hours to fully settle, agitate, drain, filter, and collect to be freeze dried. Ice water hash is graded on an informal scale by “stars”. This starts at one-star, going all the way up to six-star, which is considered a “full melt” product. A full melt ice water hash is the best SKU that a standalone ice water hash can be and means that it fully melts, leaving no char behind when dabbed. Most live rosins are made from four-star or five-star ice water hashes, and three-star or below are often used for infused pre-rolls, edibles, and topicals.

The wet trichomes post-wash form a type of granular paste akin to wet sand which is smoothed in the trays and then dried in a freeze dryer. That process takes an additional 8 to 24 hours, depending on the type of freeze dryer used and the amount of hash being dried. When freeze drying, most operators do so at low shelf temperatures to enhance terpene retention for the best possible final product.

Before committing large production-sized runs to ice water hash, it’s worth doing small test washes of a pound or less if possible, to deduce yields. Your finished price per gram can vary greatly, so knowing if the material you have on hand is ideal for solventless or not prior to running multiple batches of it can help your bottom line. Experimentation is always a part of the process however, and while you will invariably encounter wash batches that don’t hit your target yield numbers, they may very well be extremely flavorful or aromatic that customers are excited about. If a strain doesn’t wash perfectly, don’t get discouraged – keep washing new material until you find your roster of winners.

Finished SKUs

Once your operation has finished its first batch of dried ice water hash, you will then do one of the following: press the ice water hash on a rosin press to create live rosin, package the ice water hash as-is to be sold, infuse the ice water hash with pre-rolls, or otherwise infuse the ice water hash into edibles, topicals, or tinctures. The amount of post processing required will vary but is primarily the domain of live rosins. If you want to simply offer a hash rosin badder or butter, the process is very simple. Ice water hash is placed inside of a mesh or stainless steel filter bag, pressed at relatively low temperatures, (140°F – 200°F is a common range) and then collected. Using a rosin press that offers high levels of precision over your temperature, force, and other key variables is crucial to create a consistent live rosin product. For live rosin sauce, diamonds, and cartridges, a mechanical separation process is required. This can take anywhere from 10 minutes to a week or longer depending on the desired result once the live rosin has been pressed to achieve the correct consistency and stability.

Pictured: rosin dripping from the PurePressure Longs Peak pneumatic rosin press

As noted at the beginning, you want to have set out before doing your first wash with a game plan in mind of what kinds of live rosin or ice water hash SKUs you want to produce. Adjusting your solventless SKU lineup to match your market and potential customer base is an important step. For example, in more mature markets, more expensive dabbable live rosins and full melt ice water hashes are in higher demand because consumer taste preferences evolve to seek better and better products. For newer markets, being one of if not the first brands to launch this kind of product can potentially offer large competitive advantages. Live rosin in its various textures tends to be the top seller for most solventless processing operations, so using this as a guide point can help your operation branch out over time to offer additional solventless SKUs.

The different types of final SKUs that can be produced with solventless should be based on what you believe aligns with your brand, and your operational goals. If your company is billing itself as a truly high-end concentrate brand, you need to set your sights on making full melt ice water hash, top shelf live rosin, and solventless cartridges. On the other hand, if your company is more focused on edibles for example, then producing a hash rosin-based edible can be a massive differentiator against your competitors. You can then also expand your solventless SKU lineup to then start making a foray into dabbable grams of rosins or ice water hash SKUs.

One way to visualize this selection process is to think about the different types of consumers and what types of solventless SKUs may be attractive to them. The graphic on the right details what kinds of SKUs different consumers are likely looking for, depending on their personal consumption habits or expertise.

Although this data is somewhat old in today’s rapidly evolving cannabis market, age and gender do seem to impact product choices as well. Whereas men tend to buy more concentrates than women (7.3% of products purchased, versus 5.6% for women), and younger demographics also purchase more concentrates (roughly 8% of purchases for those in their 20s compared to around 4% for those in their 70s) (Headset.io, 2016). Anecdotally, many live rosin and ice water hash consumers tend to skew younger and male, so understanding what makes this demographic tick is essential. Since live rosins and ice water hashes can be made into so many different SKUs, the determination on what should be produced is a mixture of ability level of the solventless extraction division itself, the perceived maturity of the market that is being operated in, as well as what SKUs might best align with an individual company’s brand or ethos.

Another tip for newcomers into solventless or brands who want to increase their existing sales is that every solventless concentrate brand should also invest energy into educating their potential customers at the dispensary level. This can take the form of a mini flyer along with budtender education. Solventless SKUs virtually always carry a higher price point than their solvent-based competitor products, so high quality package design can also go quite a long way to get a customer to make that first purchase. Giveaways, discounts, and other incentives to ensure that the people in the dispensaries who are actually responsible for selling your solventless products can help better ensure the success of a product launch.

Lastly, a key category that should be targeted for any solventless extraction business are solventless vaporizer cartridges. In both Canada and in the United States, the growth of vape pens is undeniably strong in spite of the vape crisis of 2019 (The Marijuana Business Factbook, 2019). Whereas in 2019, true, 100% solventless rosin vape cartridges were quite rare, this product is proliferating quickly as perhaps the top of the line luxury vaporizer. Making them requires mastery of the ice water hash process however, and many solventless businesses set an end goal of making solventless vapes to round out their SKU lineups. This helps attract more lay consumers who are interested in buying a higher quality vape than what is commonly sold on the shelf, but who aren’t necessarily the type of people who own a dab rig.

Setting your solventless business up for success by perfecting your live rosin process is an essential step for most operations who want to grow a solventless extraction division. While there are many ways to achieve profitability with live rosins, focusing on curating premium material and washing it properly, consistently, is what sets the biggest and most successful solventless processors apart from the rest.

Works Cited

BDS Analytics. (2020, May). STATE RETAIL SALES REPORT MAY, 2020. Retrieved from BDSA: https://www.oregoncannabisretailers.com/resources/BDSA%20Analytics%20Monthly%20Sales%20Report%20-%20May%202020%20-%20OR.pdf

Headset.io. (2016, July). What Does the Average Cannabis Consumer Look Like? Retrieved from Headset.io: https://www.headset.io/industry-reports/what-does-the-average-cannabis-consumer-look-like

Porter, N. (2017, March 11). Cannabis Plant Anatomy: Trichomes 101. Retrieved from Medical Jane: https://www.medicaljane.com/2017/03/11/trichomes/

The Marijuana Business Factbook. (2019). Annual Marijuana Business Factbook. Denver: Marijuana Business Daily.