The Process of Making Hash Rosin: Explained

Live rosin is one of the purest, highest-quality cannabis extracts on the market, sought after by the most discerning connoisseurs. The product offers excellent profit margins and can strengthen the value of any extract brand, but a lot of manufacturers understandably don’t know where to begin.

Grams of live rosin made by Papa's Select (Instagram: @papas_select)

We’ve created this guide as a step-by-step primer on how to easily introduce solventless live rosin into your product line—and to start reaping the benefits.

What Is Live Rosin?

Live rosin is a solventless extract that maintains the live essence of the plant. The cannabis curing process can sacrifice up to 95% of the plant’s terpenes, but live rosin keeps the vast majority of those terpenes intact, resulting in a product that’s more flavorful, more aromatic, and more potent. The live rosin process starts with freezing the freshly harvested cannabis instead of drying and curing it. Then the frozen cannabis is processed and extracted as a live product.

Fresh frozen cannabis flower ready for agitation

Live rosin is similar to live resin, but whereas live resin is traditionally created using solvent extraction (e.g. hydrocarbon or ethanol extraction), live rosin is completely solventless. The cannabinoids and terpenes are extracted from the fresh-frozen cannabis using only heat and pressure. That’s part of the reason why live rosin is one of the purest extracts available.

How to Make Live Rosin With Fresh-Frozen Cannabis

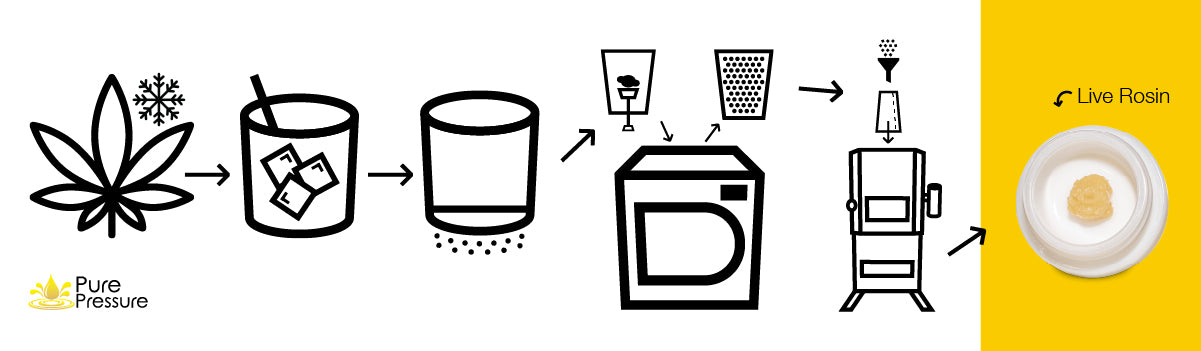

There are five basic steps to making live rosin:

- Freeze your fresh cannabis

- Agitate your cannabis in a hash-washing vessel

- Transfer your agitated cannabis trichomes to a filtration vessel

- Collect the filtered hash and freeze-dry it

- Press your hash using a rosin press

Once your equipment is set up, most of this process can be streamlined.

1. Freeze Your Fresh Cannabis

To achieve a truly live product, the first step is to freeze the freshly harvested cannabis. Don’t dry or cure. Just remove the fan leaves, cut the stock, and place the buds inside of moisture-resistant bags. Then place the bags in a freezer until you’re ready for processing. For a complete breakdown of how to achieve fresh-frozen cannabis, please refer to our comprehensive guide on How to Process Flower From Harvest to Fresh Frozen.

Frozen cannabis flower in bags

Note that this is an optional step that allows you to achieve a live product. The remaining steps can be completed with fresh-frozen or with dry cannabis, depending on your preferences and capabilities. As long as you have a high-quality starting material, you can still achieve an excellent product without freezing — as solventless extraction is the gold standard for cannabis post-processing. The fresh-frozen process will just give you a much richer terpene profile.

2. Agitate Your Cannabis

The agitation process separates the resin from the plant, allowing you to collect only the most potent compounds. This is traditionally the first step in making ice water hash, or bubble hash. The frozen (or dry) cannabis is submerged in a vessel filled with ice water and stirred vigorously to loosen the trichome heads.

There are two primary methods to complete the washing/agitation process.

- Automated agitation. This is done with the help of a device like the Axis Trichome Separator, which uses machine power to mimic hand-paddle agitation. The automated paddle is lowered into the wash vessel, where it stirs the ice water mixture according to your desired speed and interval time. This method allows you to process more material in less time, as you can automatically agitate one vessel while preparing or filtering another vessel.

Axis washing in a 65 gallon Bruteless vessel at KushMasters

- Manual agitation. The manual agitation process is basically the same, but you’re stirring the ice water on your own using a hand paddle. This method is more labor-intensive but often preferred by hobbyists and small operations.

Hand washing in 65 gallon Bruteless vessels at Papa's Select

For either method, you’ll need a basic hash-washing solution. This may be something as simple as a hash-washing vessel for home use or a complete hash-washing system for commercial use.

3. Filter Your Trichomes

Once the trichomes have been separated, the next step is filtration. For this, you have two options: gravity draining or pump filtration.

- Gravity draining is the traditional method. First, the ice water hash is agitated inside of a vessel on an elevated platform. Then it’s drained into a second filtration vessel below. The second vessel is lined with a stack of mesh stacker bags, and the hash is sieved through the bags until only the sticky resin remains. The hash is then collected and moved on to the next stage of processing (drying).

Filtration via gravity draining

- Pump filtration is a newer method developed by the team at PurePressure. Rather than draining the liquid from a higher vessel into a lower vessel, you can pump it between vessels that are side-by-side. The vessels are connected via hoses, and the hash-rich water is transferred with the help of a pneumatic hash pump. Our pneumatic hash pump is the original pump filtration solution for solventless extraction, and you won’t find a solution like it anywhere else.

Filtration via Pneumatic Hash Pump

There are some key advantages to using a pneumatic hash pump as opposed to traditional gravity draining:

- A hash pump streamlines your operations and allows for better batch-style processing. After the hash-rich water is transferred to the filtration vessel and the hash is filtered through the bags, the remaining water can be pumped back into the wash vessel (recirculated) or redirected as waste water with the help of a separate centrifugal pump, leaving you with just the hash in your filtration vessel. The wash vessel is then ready for the next batch. You can even manage multiple vessels simultaneously.

- A hash pump can accommodate labs with low ceiling heights—like cold rooms, for instance. You don’t need to elevate any of your vessels.

- The pressure and flow of the hash pump can be adjusted via individual dials, giving you full control over your speed.

- As a type of diaphragm pump (or positive displacement pump), a hash pump is ideal for shear-sensitive applications. It uses low shear forces to transfer hash between vessels without damaging the delicate trichomes.

Trichome-rich water being pumped through the Pneumatic Hash Pump at Papa's Select

To get the maximum benefit of pump filtration, you’ll want to invest in a quality commercial hash-washing filtration system. If you already have a hash-making system but you want to upgrade the filtration, you can invest in a pneumatic hash pump (to move your hash from agitation to filtration) and a centrifugal pump (to redirect your water back out of the filtration vessel).

4. Freeze Drying

After collecting your filtered hash, you want to place it into a freeze dryer to remove the residual moisture. Harvest Right and Labconco make excellent freeze dryers for commercial and industrial use, but any high-quality freeze dryer should do the trick. Just make sure that it has enough drying space to meet your needs.

Wet hash ready for the freeze dryer (L), wet hash being put in the Harvest Right (M), Dry ice water hash post freeze drying (R)

Important note: You’ll need a freeze dryer and not a conventional freezer for this step. As opposed to a conventional freezer, a freeze dryer uses a low-temperature dehydration process to eliminate water without sacrificing your terpenes or compromising the quality of your final product.

After your hash has dried, you have two options:

-

Keep it as-is.

You now have a high-quality bubble hash that you can enjoy or market on its own. Bubble hash is a highly potent product that contains up to 60% THC, and it’s suitable for vaping, dabbing, bowl topping, edible recipes, and all kinds of other infusions. If you really want to take your hash over the top, you should strive for five- or six-star full-melt bubble hash. Our blog has more information about how bubble hash is rated.

- Continue processing. If you want to achieve the maximum purity and quality, you’ll want to take the next step and press your bubble hash into rosin. A high-quality hash rosin can have a THC concentration of up to 90%, and a live hash rosin (i.e. hash rosin made from fresh-frozen cannabis) is just about the purest extract you’ll ever achieve.

Live rosin being pressed between the plates of the Longs Peak pneumatic rosin press

Still not sure which way to go? For a more comprehensive breakdown, check out our complete guide to Bubble Hash vs. Rosin.

5. Pressing

Finally, you’ll want to take your freeze-dried bubble hash and press it into hash rosin. This is best achieved using a manual or pneumatic rosin press.

To start, you’ll generally place your hash into rosin filter bags or wraps. For high-quality bubble hash and sift, our 25μm stainless-steel mesh rosin screens offer even more capacity and precision than bags.

Hash patties wrapped in 25µm stainless steel mesh, prepped to be pressed into rosin

Then you’ll place the bags or wraps between the two heated plates. The plates themselves are covered with parchment paper or PTFE sheets.

Finally, you’ll want to apply an appropriate temperature and pressure setting to your press. For high-quality hash rosin, you’ll generally want to stay within the 170°F to 190°F range, though your preferences may vary. For most applications, you’ll want to stay within a pressure range between 300 and 1,500 lbf. Try to avoid applying too much pressure, as you can end up squeezing excess fats, lipids, and chlorophyll. This can negatively impact the quality of your extract.

Pressing rosin at 175°F on the Longs Peak pneumatic rosin presses at the Papa's Select lab (Instagram: @papas_select)

Once you’ve applied your preferred temperature and pressure settings, you can press your rosin. As the heated plates are pressed together, the extract is squeezed out from between the plates and collected onto the parchment paper. The extraction process is now complete.

Required Equipment & Materials for Making Live Rosin

Just to recap, if you want to make live rosin with ice water hash, you’ll want to invest in the following equipment:

- Freezer

- Hash-washing equipment

- Hash-washing vessels

- Hash-washing platform (if gravity-filtering)

- Bubble bags

- Filtration equipment

- Mesh stacker bags

- Hash pump

- Centrifugal pump

- Hoses

- Freeze dryer

- Rosin press

To purchase commercial-grade versions of all of the above, you can generally expect to pay between $60,000 and $100,000 and up. However, given the premium quality and high volume of product that you’re able to create, you can expect a heavy return on investment in minimal time.

How to Make Other Solventless Extracts Using the Methods Above

The above method will give you the highest-quality live product because the cannabis remains frozen throughout processing. However, if you have different goals for your extraction, you might not need all of the above equipment. For instance:

- To make hash rosin with dried/cured cannabis: The process is the same as above, but you’ll start with step 2—no freezer required.

- To make flower rosin with dried/cured cannabis: You’ll focus entirely on step 5 above. Aside from your starting material, you’ll just need a rosin press and all of your basic rosin-pressing accessories (filter bags, parchment paper, collection tools, etc…).

- To make rosin with dry sift: First, extract the sift from your flower. You can extract small amounts by filtering the material through 90μm- to 220μm-micron sifting screens and then compressing the sift in a pollen press. If you need a commercial solution to extract high-quality sift, you can use a trichome extractor like the Alchemist 420. Once you have your sift, just follow step 5 above.

- To make bubble hash with fresh-frozen cannabis: Focus on steps 1 through 4 above. If you’re not taking that extra step to make rosin, you won’t need the rosin press.

- To make bubble hash with dried/cured cannabis or sift: Focus on steps 2 through 4 above. You’ll just need to agitate, filter, and freeze-dry your starting material.

The great thing about possessing all of the equipment on the list above is that you can create any combination of these products. Establish a diverse line of premium-grade, connoisseur-friendly cannabis extracts, and reap the rewards again and again.

How Live Rosin Is Made - A Recap

We’ve thrown a lot of information at you, but the process of making live rosin isn’t too complicated once you get started. You’re really just preparing your starting material, transforming it into high-quality hash, and then pressing it into rosin. Beyond that, there are just a few things to keep in mind:

- You don’t have to start with fresh-frozen cannabis, but it will yield the highest-quality product.

- If you have the budget for it, pump filtration is far superior to gravity filtration.

- Don’t confuse your pumps. A hash pump is ideal for moving hash from the agitation vessel to the filtration vessel. A centrifugal pump is ideal for recirculating your water or eliminating it from the filtration vessel.

- If your goal is to make rosin at a commercial level, it’s best to go with a pneumatic rosin press like the Longs Peak or Pikes Peak V2. For smaller batches, you can use a pneumatic or manual press like the Helix and Helix Pro.

With this process, the sky’s the limit. You can create all kinds of valuable SKUs, including dabbable concentrates, edibles, vape cartridges, topicals and more, all potent and super high-quality. If you’ve been looking for a way to achieve a competitive edge in the cannabis market, look no further.

If you need any assistance, the knowledgeable team at PurePressure would be happy to answer your questions or help you to get up and running. Click here to talk to an expert today.