Top 5 Tips & Tricks for Pressing Hash Rosin

Learning how to press excellent hash rosin is a skill all producers and growers should know. The highly potent, solventless option provides businesses with a base to create an array of products that will maximize the brand name and its revenue. With concentrates dominating market shares, and numbers only expected to increase, now is the time to understand how to press hash into rosin like a pro.

Consider these five tips to help you best understand the process of hash rosin pressing. These tips should provide you with some insight into how you can go from rosin novice to professional in relatively short order.

Hash Rosin Tip #1: Pressure - Less is More

Whether you are pressing whole flower, dry sift, or ice water hash, too much pressure, especially too quickly, can ruin your extract.

Older era methods may suggest otherwise, as it is the practice for obtaining maximum yields. But, if you want top quality rosin, a light touch with your force is the way to go. Applying too much pressure to your hash at once can result in your rosin bag slipping (also called "hydroplaning") between the heat plates or blowing out.

Check out this video with Eric Simpson (Instagram: @simpsonsolventless) from PureCannalabs on how to properly apply pressure to avoid bag slippage. Keep in mind that the better the quality that the hash is, the more likely it is to slip during the press. This is due to the fact that properly grown, higher quality trichomes are more resinous which creates a slippery surface.

You can control your extraction whether using a manual press like the Helix and Helix Pro, or an automated commercial press like the Pikes Peak and Longs Peak. Set the pressure in your settings, or simply apply the adequate amount of pressure yourself (we even give you recipes to follow along that were developed by solventless experts). No matter what rosin press you use, try to press as gently as possible as you get started, and then increase your force over time to maximize your yield. This tip is particularly important when working with hash and sift rosin as no one likes a blown bag or wasted time.

Hash Rosin Tip #2: Temperatures May Vary

The temperature you press your hash at depends on a few things. The quality and age of the starting material as well as the end product you are going for will both be factors that determine your press temperature.

Higher quality material requires less heat for a complete extraction. This applies to any source material, be it flower, sift or ice water hash. The opposite applies to older, denser flower, sift, or hash, as well as lower quality material in general. This is because additional heat is required to break down the trichome heads, which if they aren't all already broken or damaged, are likely dried out or simply oxidized.

In general, we recommend keeping your rosin press temperature below 220°F no matter what you are pressing, and often much lower when pressing high quality sift or ice water hash (140°F - 180°F is common for the highest quality sift or bubble hash).

The key is to experiment on your own. Consider rosin pressing like cooking - different types of foods require different temperatures to bring out their full flavors, however the boiling point of terpenes varies widely (and many are well above 350°F). You don't want to get anywhere near there, as significant terpene degradation can happen well below the boiling point, but the point is that not all strains need to be pressed at the minimum temperature. Play with different heat settings on your rosin press with small samples to find what works best for you.

Temperature variations can modify terpenes, and in some cases can destroy them. In other cases, they can lead to improved yield results, so like any craftsman or artisan, you have to know exactly what you're working with which can take time.

Hash rosin pressed on the Helix at 210°F - warmer than many expect with excellent resulting quality and clarity

Hash Rosin Tip #3: Advanced Extractions and Mechanical Separations Require Patience

Learning how to press rosin is a craft that anyone can do with practice. However, it is one with less of a learning curve than other forms of solvent-based extractions. While a rosin maker will need some time to understand the precise craft and learn the machinery, they should have the basics in no time.

Mastering advanced extractions will take additional practice, both from a user's learning perspective and from the perspective of the extraction time itself. Those looking to conduct terpene separations using bubble hash or premium sift will need patience, because often these require multiple presses and long presses (20 minutes or more in some cases). The same goes for creating solventless cannabinoid extractions, like THCA isolates.

Practice makes perfect. To ensure you’re practicing with the ideal material for terpene separations, use a good amount of high quality hash. While this isn't always possible for a home grower, aim for 50 grams or more for a proper terpene separation, however many labs are processing 100 grams or more at a time. Use a low temperature to start and do a long test, such as 120°F-150°F. Have no fear, that is okay, and the key is to keep a close eye on it. For large quantities of hash or sift, it takes time for the heat to penetrate the material to begin the separation process.

Creating solventless THCA diamonds requires something different, namely much higher temperatures after you've pressed out your terpenes. It often requires multiple presses as well to conduct a proper extraction. Doing so, “cleans” the material as it reaches 300°F when it forces the THCA from the bag, which then quickly nucleates.

When performing mechanical separations, extremely fine filtration is a must to properly get the job done. Our 5µm nylon mesh wraps or the 25µm stainless steel mesh is perfect for this. When the 5µm nylon is used inside of the 25µm stainless steel, the nylon does all of the filtering while the stainless steel provides structural reinforcement to prevent a blowout. The combination of two filtration types dramatically improves the filtration quality of your solventless oil.

How to wrap your hash patty using the 25µm stainless steel mesh

Be sure to have plenty of material when starting out attempts to perform any solventless mechanical separation technique. Use only top-tier material as mid-grade cannabis won’t do well. There simply are not enough cannabinoids or terpenes to extract properly, which often results in frustration because of wasted material that could have been perfectly good mid-grade hash rosin or food grade rosin. While all rosin presses in our line work here, our Helix and Helix Pro models allows even at home pressers to get a more hands-on understanding and appreciation for the process.

Hash Rosin Tip #4: genetics matter

One of our key rules is “fire in = fire out.” Quality means sourcing a great strain for pressing rosin that is grown properly and contains resinous buds with high cannabinoid content. That entails finding profiles with ideal trichome structures that provide a rich balance of flavor, aroma, and effects.

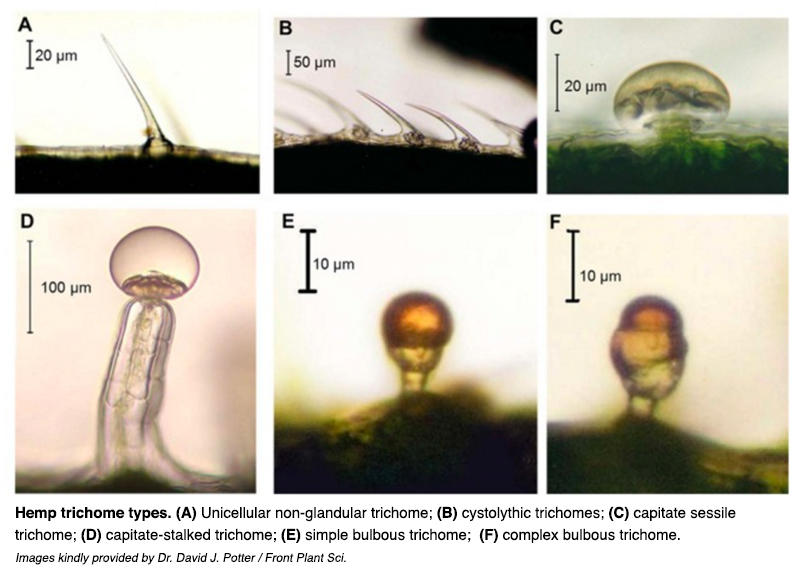

There are endless breeds of cannabis that you could choose to extract from. When it comes to making solventless hash though, the trichomes that the plant contains are going to make or break your process. As you can see in the diagram below, the types of trichomes found on cannabis can take on multiple shapes and sizes. Image D shows a capitate-stalked trichome, which is the ideal size and shape to look for if you are looking for genetics to process solventlessly. For more on selecting strains for ice water hash processing, check out this article.

Image source

Seek out genetics that are already known to be successful solventless strains. Consider starting your experimentation with a few reliable strains and keep them in rotation. Once you master the extraction process of the first few, experiment with new cultivars. It is important to note that not all strains have the right genetic makeup for solventless processing.

To get started, we recommend trying any of the following:

- GMO & Crosses (Garlic Cookies)

- Chem Dawg, Chem Strains

- Gorilla Glue, Glue Strains

- Ice Cream Cake and Gelato Strains

- Do-si-dos, Cookies & Cake Crosses

- The White, White Fire, White Crosses

- Clementine & Banana Split (DNA Genetics)

- MAC (Miracle Alien Cookies)

- Papaya & Related Crosses (Oni Seed Co)

- Sour Kosher, Many Sour Strains

- Purple Punch & Many Pie Strains

Be sure to follow top strain producers, reviewers, and other news outlets as well for more flower suggestions.

Hash Press Tip #5: textures may vary, variable control helps significantly

Don’t beat yourself up if you aimed to create budder but ended up with another texture. This is part of the learning curve and is quite common. This can happen when understanding the capabilities of your rosin press, as well as simply with certain strains behaving differently. Extremely precise variable control makes all the difference, and is something you will learn as you press more.

Once pressing is mastered, hash rosin provides producers with the most flexibility, resulting in a number of textures such as shatter, badder, sauce, diamonds, and more. From here, producers can create dabbable concentrates, vape cartridges, edibles, tinctures, topicals, and other popular products.

Keep in mind that producing concentrates and various textures requires an understanding of rosin press post processing techniques. It is also key to know the importance of post-press cooling and further post-press processing such as cold curing, oven curing, and low heat terpene separations. Many textures are formed based on the initial temperatures used, as well as post processing techniques, such as "jar tech" which is where terpenes naturally separate from rosin in a glass jar using a variety of temperature manipulation and air exposure methods.

Practice makes perfect. With the proper flower and equipment, your learning curve should reduce greatly. If you are ready to jump in but feel that you may need additional guidance, our sister company PureCannalabs offers thorough training on the entire hash rosin extraction process. Whether you're seeking training specifically on cartridge making or you are just getting started with your press, each training service is catered specifically to the client's needs and goals. Contact the PureCannalabs team today to get started.